Because every aspect of your production should run smoothly

Production plants and systems that always go two steps further

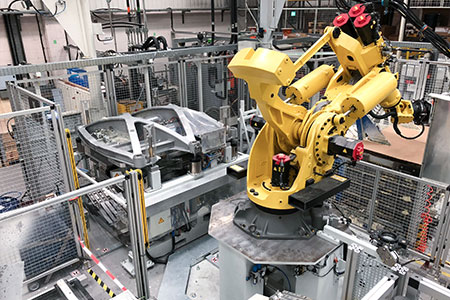

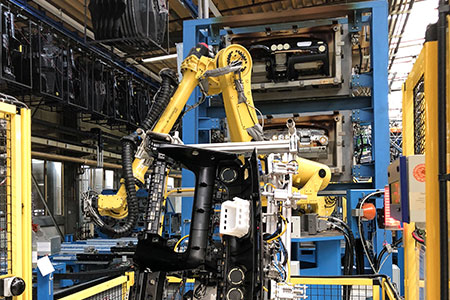

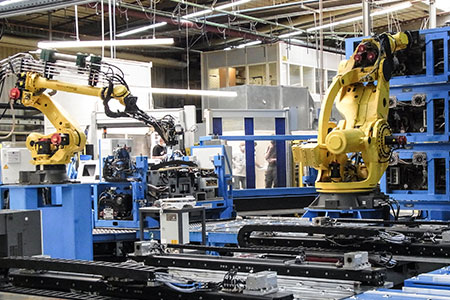

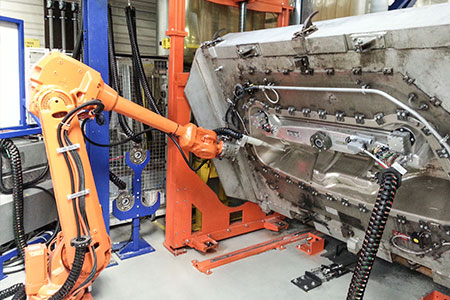

You should rely on equipment construction that integrates all production-specific and automated production areas, and in which tool carriers, assembly systems and handling technology harmonize optimally with the internal materials-handling technology. Considerable savings potential in terms of manual work and personnel deployment are possible here. Especially for the automotive industry, we increase efficiency by integrating robot cells into production. By perfecting our production processes, we have also been able to achieve a significant reduction in scrap quantities and raw material consumption.

Our products

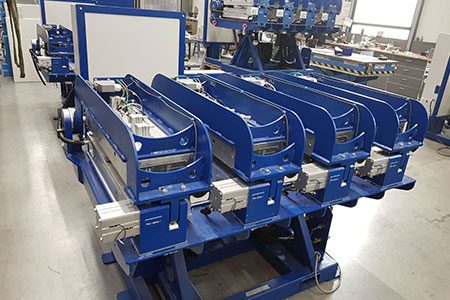

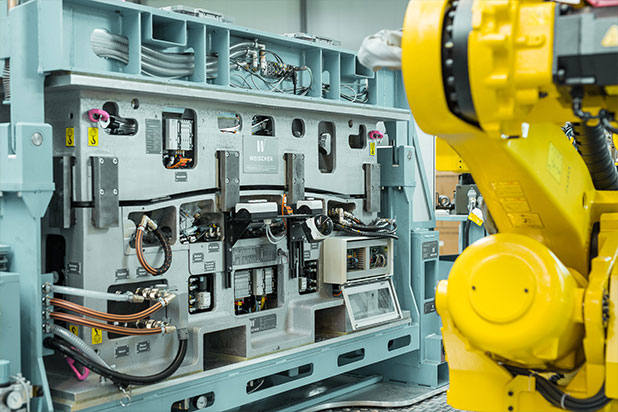

For the most diverse types of foaming tools and laminating tools. The illustrated examples show ultra-modern, optimally compact tools for the backing foams of instrument panels, as well as crocodile mould carriers and butterfly mould carriers for smaller components. The hinged tool carriers have opening angles from 90º to 180º and an ergonomic adjustment or a foaming layer adjustment. We exclusively use servo-geared motors from reputable manufacturers for precise, rapid and energy-efficient movements. The controls and operating elements always comply with the latest standard of technical development.

Deep-freezers and the suitable doors are manufactured almost fully automatically with Weischer's innovative technology. The plant checks the inserted elements for dimensional accuracy and it adjusts all of the necessary parameters like foaming quantity, air-bag pressure and position of the supporting elements. The result is manufacturing almost free of rejects.

A completely new dimension in the manufacturing of foamed parts: the Weischer FIP Centre. The highest flexibility is ensured by various programmes in cyclical time. Variations in the customer's call-forward notices can be adjusted live and without losses. The tools are changed without the plant standing still and while the production is running. The advantages of the turntable and of the standing mould technology / punching die technology are combined. High numbers of pieces can be manufactured through extreme modularization of the working steps. We would gladly describe the Weischer FIP Centre's further advantages to you in a personal discussion.

On account of our many years of experience in the areas of automation, robotics and making control systems, we are able to modernize older plants so that they comply with the latest standard of technical development. The control systems and drives, as well as the use of robots, can achieve a better coefficient of performance and a higher efficiency for your existing plant.

© Josef Weischer GmbH 2025