Products

Products

Our Product Range in Gauge Construction

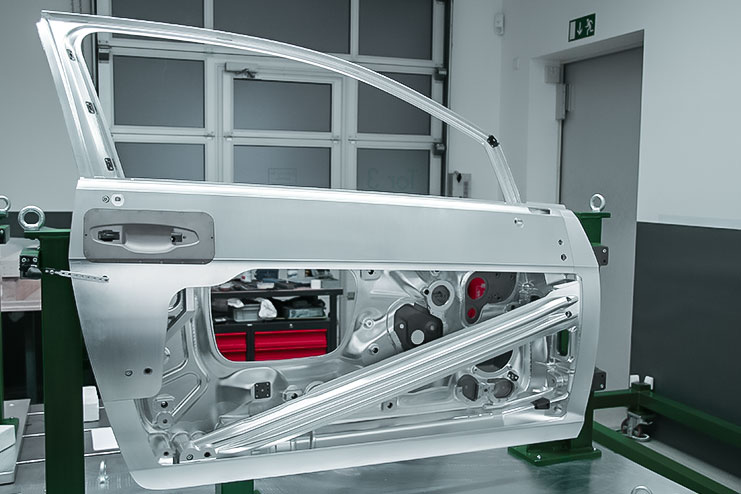

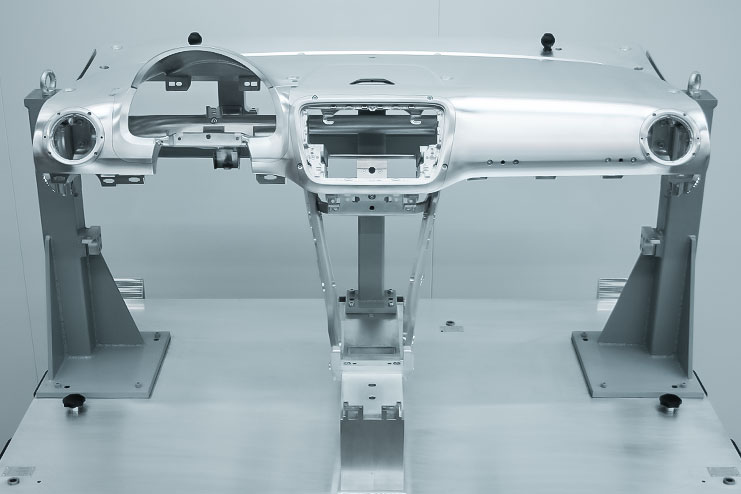

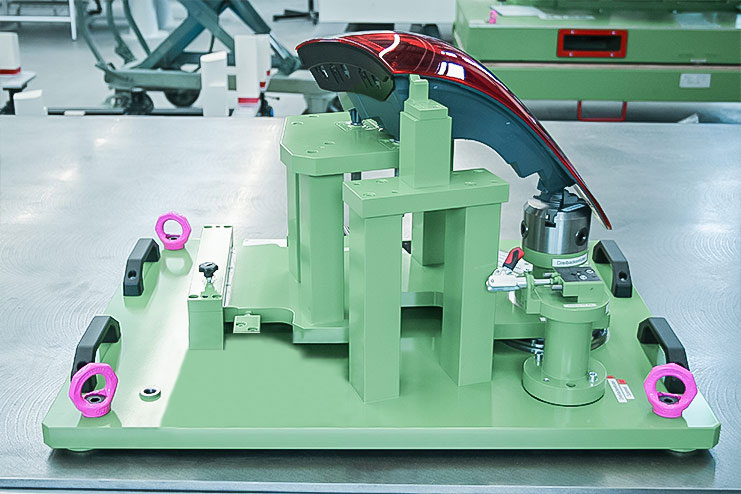

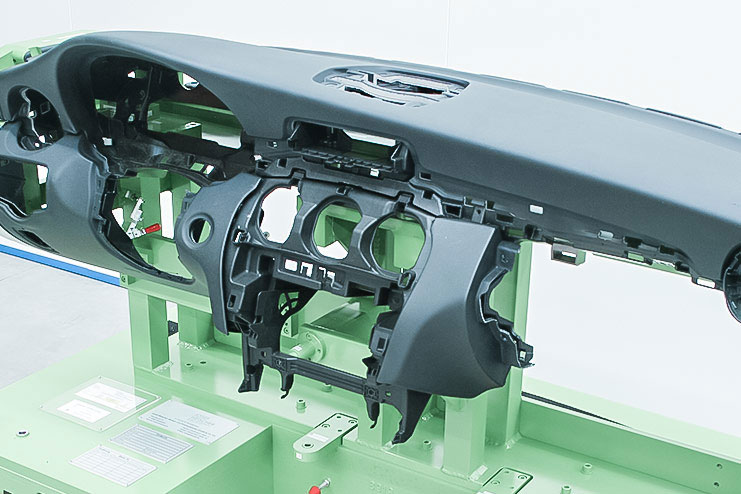

We supply our products to numerous OEMs and large system suppliers: Cubings, joint models, data control models and cut-out gauges, ZSB gauges, testing and installation gauges, component gauges, measuring fixtures and testing devices.

Our Products

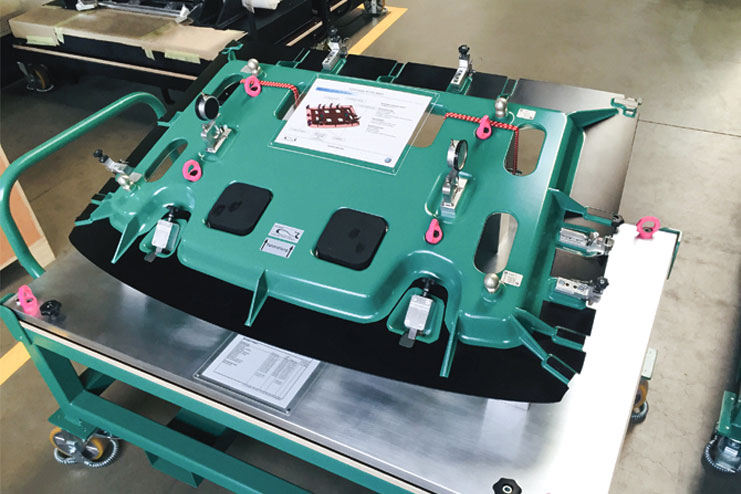

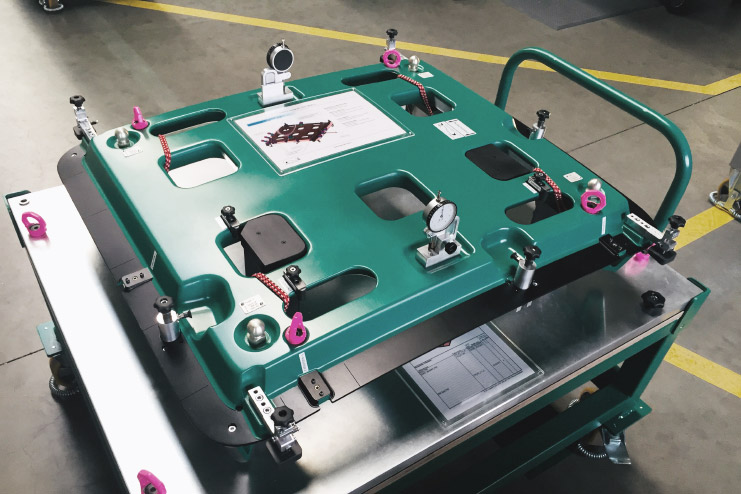

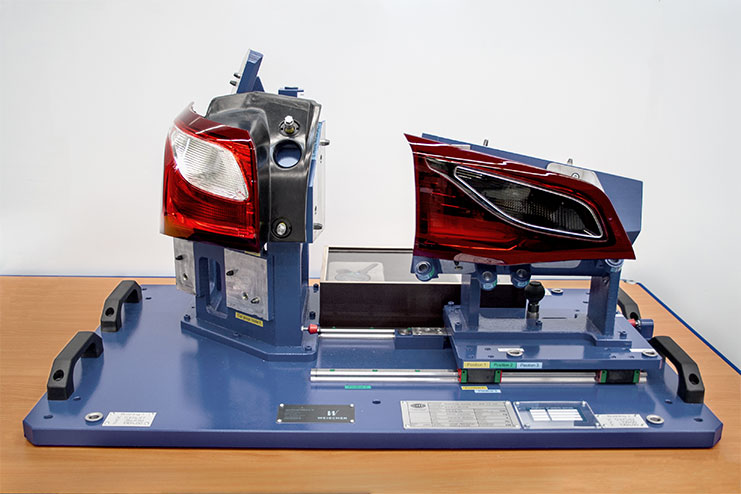

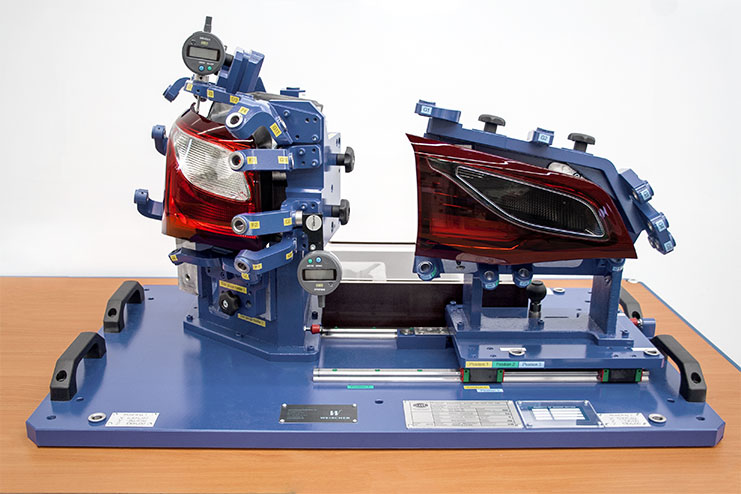

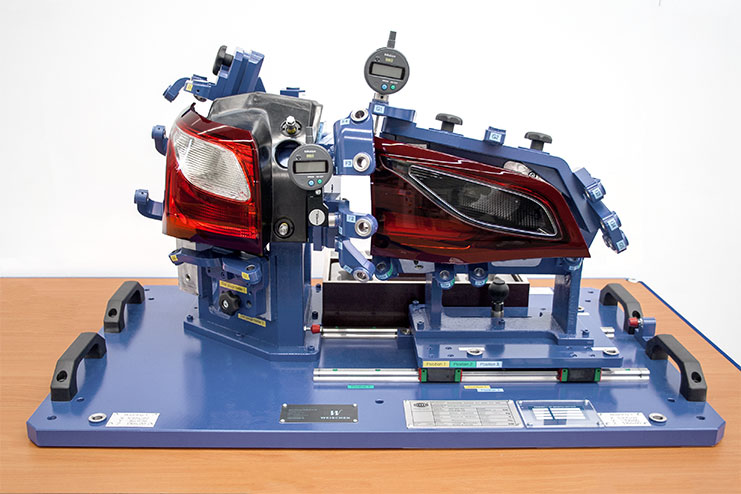

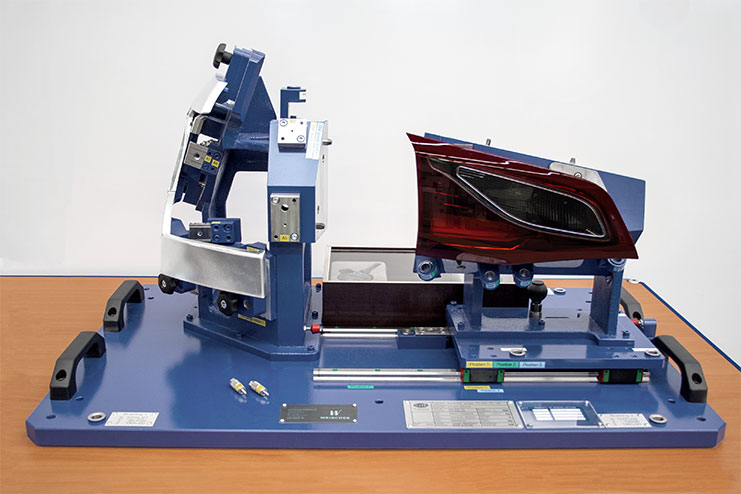

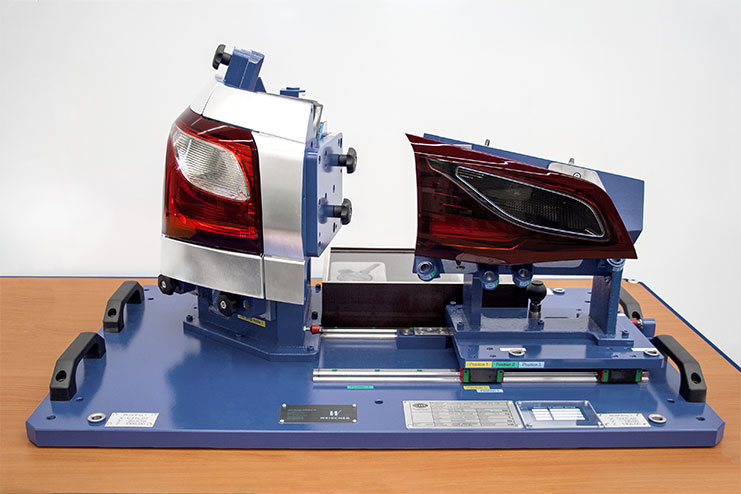

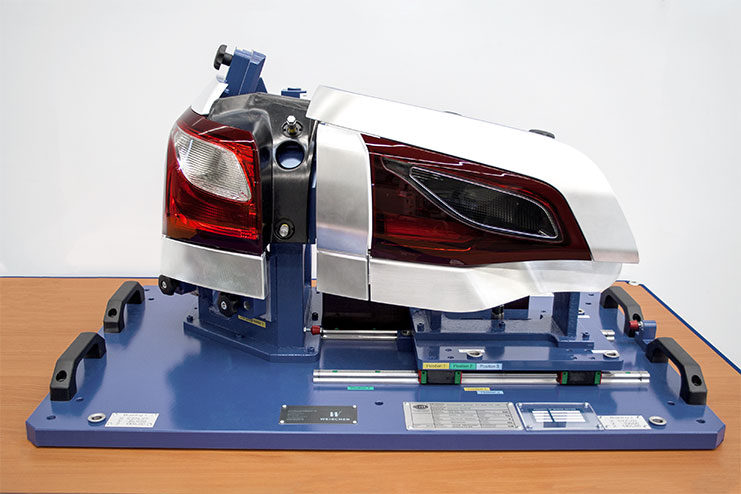

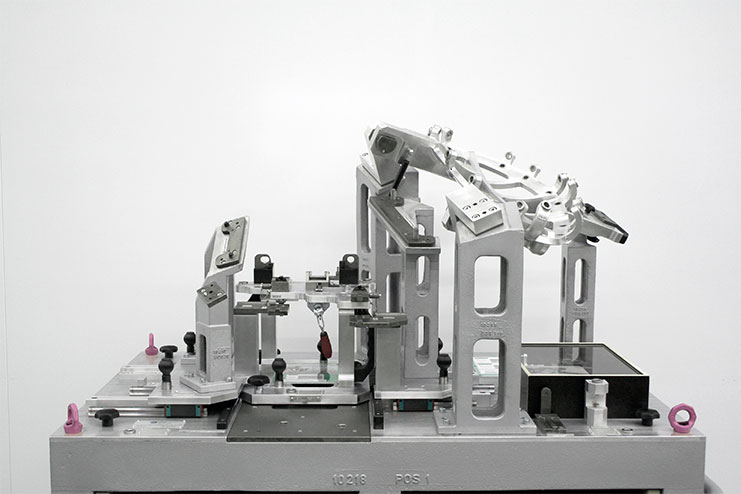

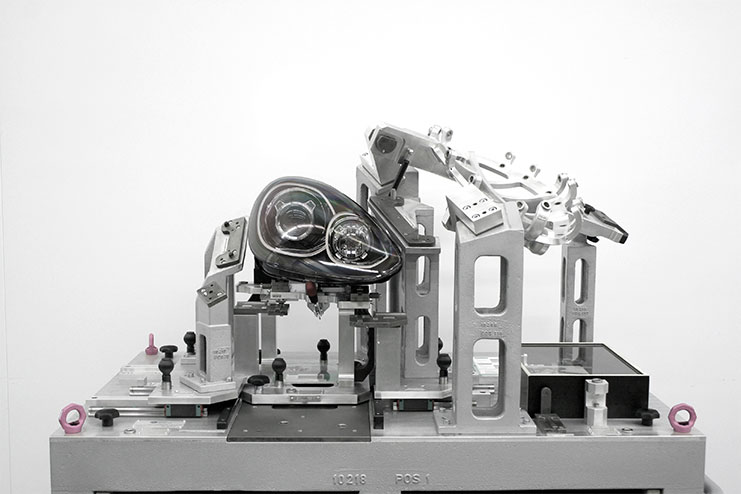

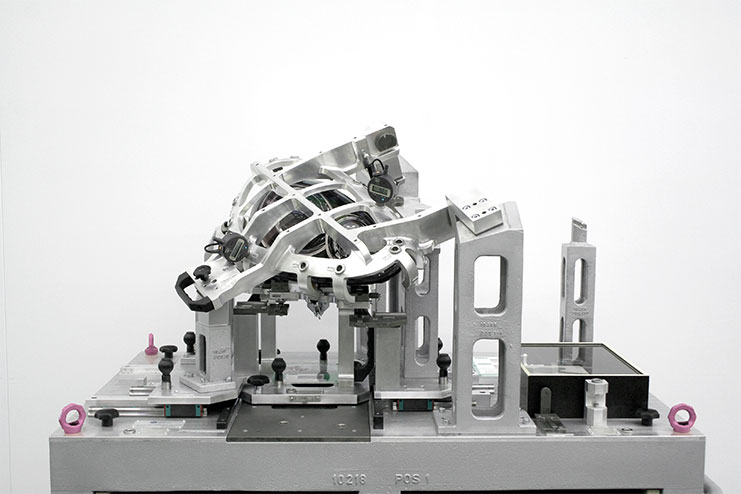

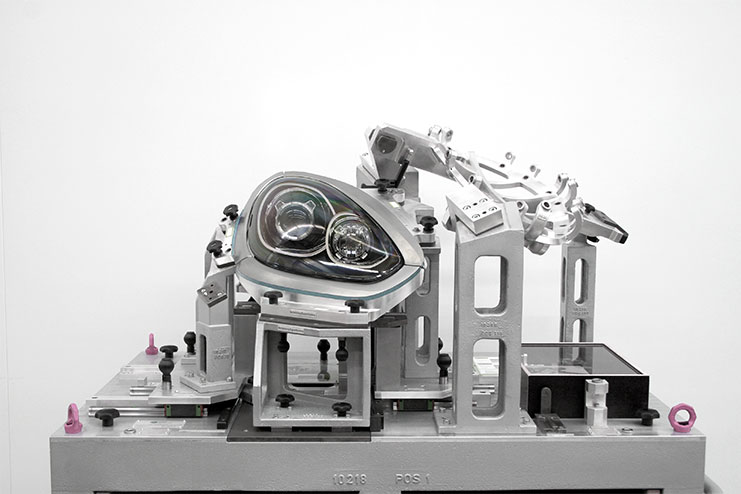

We manufacture ZSB gauges for checking and analysing component quality: for small components; for example lamps; for highly complex components such as bumpers or front-end modules; and for the interior as well as the exterior area.

Fixing points can be defined, add-on parts can be added or designed as a 0-part according to the corresponding data. The measurement is digital, so that the data can be recorded and evaluated cleanly.

Serial Recording 01 Control devices 1 1

Serial Recording 02 Control devices 0

© Josef Weischer GmbH 2025